FluiMix LNG

Sampling System

Precision Sampling Solutions for Reliable LNG Custody Transfer

Our Solutions

FluiMix LNG

Sampling System

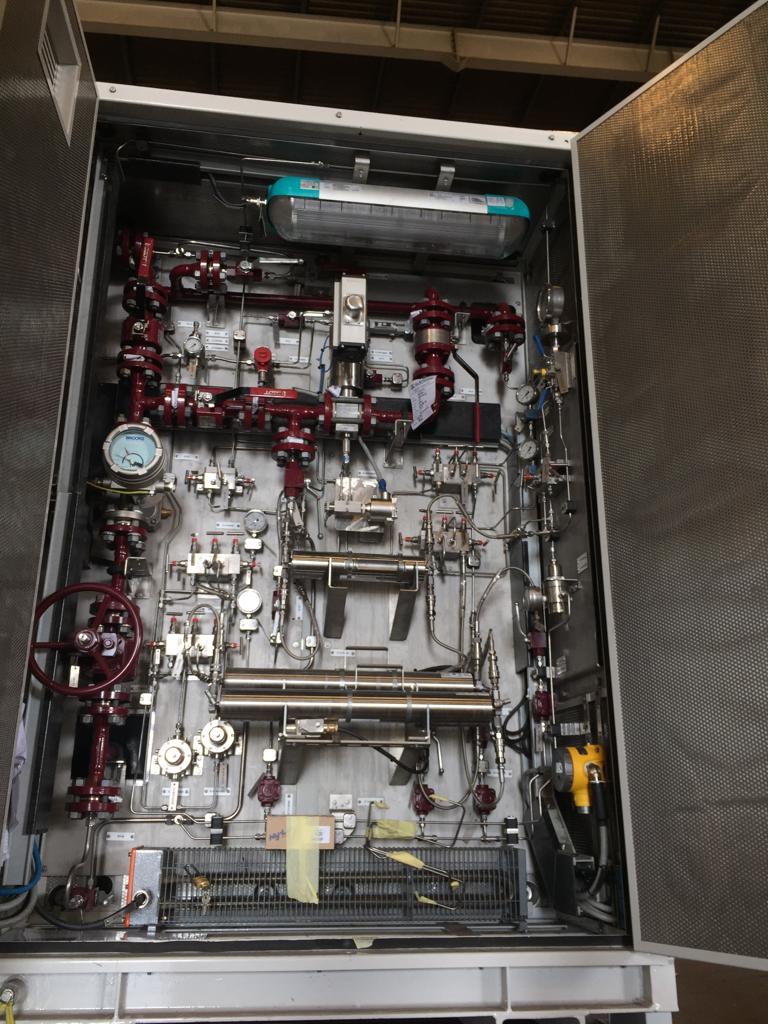

The FluiMix LNG Sampling System is a precision-engineered solution designed to ensure accurate and representative sampling of liquefied natural gas (LNG) during custody transfer and quality verification processes. This advanced system combines LNG vaporization, stabilization, and control technologies into one integrated platform, enabling consistent phase change from liquid to gas with minimal lag or deviation.

Once vaporized, the gas is kept above its component dew points to preserve the integrity of the sample. It then flows into a standard gas sampler, where samples are transferred into Constant Pressure Cylinders (CPC) using a variable volume piston mechanism that maintains fixed internal pressure throughout the sampling process.

To enhance reliability and accuracy, the system typically uses a three-sampler configuration within a single process loop. This design enables the collection of three independent yet comparable composite samples. Additionally, it supports fixed-volume spot sampling at key batch intervals (25%, 50%, 75%, and 100%) into 500 ml receivers, which are purged before use to ensure accurate point sampling across the batch.

This method significantly improves representativity over traditional approaches due to the large volume of gas that flows through the system, guaranteeing that both the extracted samples and the gas analyzed by the gas chromatograph (GC) reflect true process conditions.

Key Features

The FluiMix LNG Sampling System ensures accurate, reliable, and compliant LNG sampling for custody transfer and quality checks.

Integrated LNG Vaporization & Stabilization

Controlled phase change from LNG to gas with minimal thermal lag ensures consistent and accurate sampling conditions.

Dew Point Preservation

Maintains the vaporized gas above dew point to prevent component loss or condensation during sampling.

High-Integrity

Gas Collection

Gas samples are collected into Constant Pressure Sample Receivers (CPC) using variable volume pistons, minimizing atmospheric exposure and contamination.

Triple Sampler Configuration

Three independent samplers operate in a single loop to provide multiple, comparable composite samples, enhancing data reliability.

Spot Sampling Capability

Enables point sampling at 25%, 50%, 75%, and 100% of the batch using conventional 500 ml receivers, with purging for improved sample fidelity.

Enhanced Representativity

High gas flow volumes through the system ensure representative sampling and consistent feed to the gas chromatograph (GC).

Minimized Cross-Batch Contamination

Fixed pressure sample receivers reduce the risk of contamination between batches and protect sample purity.

Optimized for Custody Transfer

Designed to meet the rigorous accuracy and repeatability standards required for LNG custody transfer and regulatory compliance.