Products & Services

Unveiling the Essence and Expertise of FluiMix™

FluiSampler®

Introducing FMX-API-CA® and FMX-API-CE®: Dual Choices for FluiSampler® Solutions

FluiSampler ®

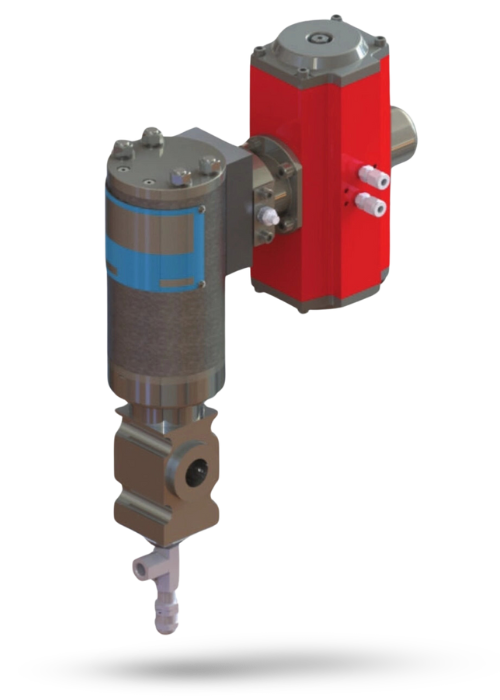

FMX-API-CA®

The FluiMix® FMX-API-CA® point sampler represents an advanced anvil piston instrument (API) cell sampler meticulously engineered to excel in the most challenging hydrocarbon liquid scenarios. Leveraging the advantages offered by bypass or fast loop sampling systems, the FMX-API-CA® sampler is exceptionally well-suited for the sampling of diverse liquids, with a particular focus on crude oil, condensate, and oil-water mixtures. Notably, this sampler is particularly ideal for applications involving energized mixing and blending.

The pneumatically operated FMX-API-CA® sampler enhances the precision and consistency of hydrocarbon fluid sampling. This sampler delivers exceptional performance and a prolonged operational life, reducing the requirement for maintenance, additional accessories, and service time. It is equipped with a 180-degree pneumatic actuator and a scotch yoke design, ensuring consistent performance across a broad spectrum of air supply conditions, process pressures, and viscosities. Additionally, the optional diamond-like carbon (DLC) coating safeguards the unit against abrasion and fortifies its resistance to various substances, including H2S, mercaptans, SO2, mercury, and more.

FluiSampler®

FMX-API-CE®

The FluiMix® FMX-API-CE® Sampler is tailored for inline sampling applications. This electrically operated sampler, FMX-API-CE®, enhances the precision and consistency of hydrocarbon fluid sampling. Utilizing the principles of a scotch yoke and lost motion, the FMX-API-CE® Sampler effectively resolves the issues associated with air-actuated samplers and eliminates the need for additional accessories. It employs a flow-through design with bottom discharge, effectively removing the need for oil/water separation.

An electric motor drives a scotch yoke mechanism, which, in turn, operates the capture tube. During its motion, the capture tube generates a fixed volume, and the sampler’s design incorporates a distinctive non-return valve and a precisely defined actuation speed to ensure a consistent and representative sample. The sampling frequency adjusts based on the flow rate.

The FMX-API-CE® Sampler employs an advanced seal design for improved performance and reduced maintenance requirements. The modular construction and seal design notably streamline the unit’s servicing process. For added durability in the harshest process conditions, optional DLC/DLD coatings extend the unit’s service life.

The FMX-API-CE® Sampler is well-suited for the sampling of various liquids, with a particular emphasis on hydrocarbon liquids like crude oil and oil-water mixtures. It is particularly ideal for applications involving energized mixing and blending.

FluiMix Products

Lab Mixing System

The FluiMix Laboratory Mixer is purpose-built for blending wet and contaminated oils and/or condensate, often sourced from pipeline samples in Fiscal Metering and Custody Transfer applications. In the time lag between sampling and laboratory analysis, certain heavier components like water tend to settle and segregate. Consequently, it becomes imperative to thoroughly mix the contents of the receiver to ensure product homogenization before extracting a sub-sample for analysis.

FluiMix specializes in crafting mixing systems, which can be integrated into sampling systems as permanent installations or employed as standalone units within laboratory settings. These mixing systems seamlessly interface with our sample receiver cans and can also be adapted for use with vessels from other manufacturers by utilizing suitable adapters.

FluiMix Products

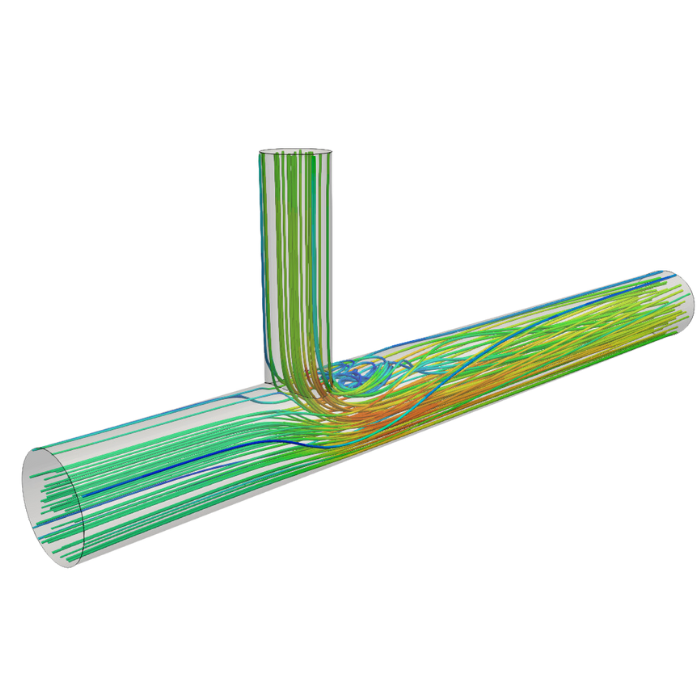

Computational Fluid Dynamics Analysis

Utilizing Computational Fluid Dynamics (CFD) offers a robust method to simulate fluid flow, heat transfer, and related processes across various scientific and engineering applications. Unlike traditional experiments that provide data from limited system locations, CFD enables analysts to explore numerous areas within the region of interest, generating a comprehensive set of flow parameters for detailed analysis. CFD allows for the theoretical simulation of any physical condition.

Fluid dynamics play a crucial role in numerous aspects of the Petrochemical industry. While physical prototypes remain integral for later stages of development, leveraging CFD studies during earlier stages can significantly expedite design and optimization processes.

FluiMix Products

FluiController®

The FluiController Model is a specialized logical control system with the ability to oversee and manage any FMX-API® cell or probe sampler. This controller can be operated either through the local interface or from a remote location. Here are the key features and benefits of this technology:

- Capacitive touch user interface

- Electric or pneumatic cell and probe FMX-API® samplers

- Flow, proportional, or batch control

- Receiver / CPC switching

- Weigh scale(s)

- Performance factor calculations

- Remote Start/Stop

- User definable alarms

- Remote operation via Modbus TCP/IP

- Safe area option available

FluiMix Products

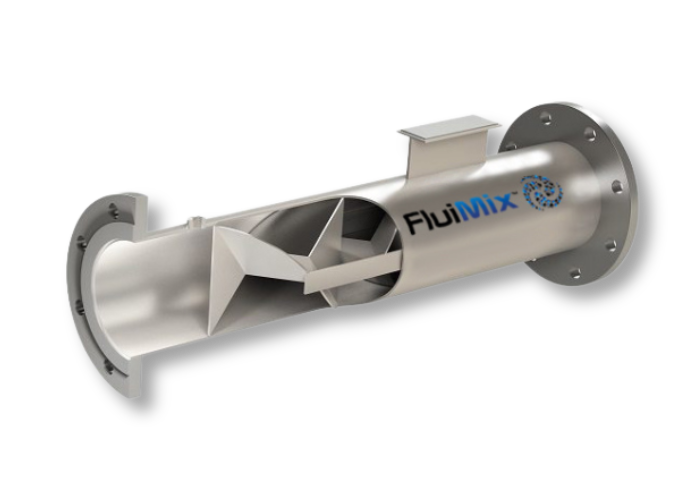

Static Mixers

Static Mixers are sophisticated stationary mixing devices designed for the continuous inline blending of fluids in pipelines. These devices have no moving parts and instead utilize the energy of the flow stream to ensure consistent, cost-effective, and reliable mixing. FluiMix offers standard sized static mixers that are readily available for direct purchase, or they can be custom designed to meet specific mixer requirements. These static inline mixers are capable of handling a range of flow rates for various applications, making them a dependable, long-lasting, and efficient solution for your motionless, continuous mixing needs.

FluiMix Products

Sample Receiver Can

Our line of ASME portable stainless steel pressure vessels has been meticulously designed to fulfill the needs of a wide spectrum of general-purpose fluid handling applications. These vessels find utility in various industries, including chemicals, life sciences, pharmaceuticals, electronics, dairy, as well as food and beverage. The vessels boast fluid capacities spanning from 3.8 liters to 37.8 liters, and larger sizes can be made available upon request.

Each model within our range is adaptable and can be equipped with air agitators, gauges, fittings, dip tubes, and custom-sized tubes to cater to specific requirements. Furthermore, diverse surface finishes are also an option for each model, allowing for flexibility in meeting varying industry standards and preferences.